Sheet Metal Flat Pattern Drafting

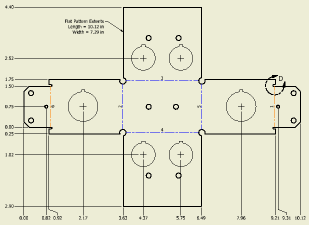

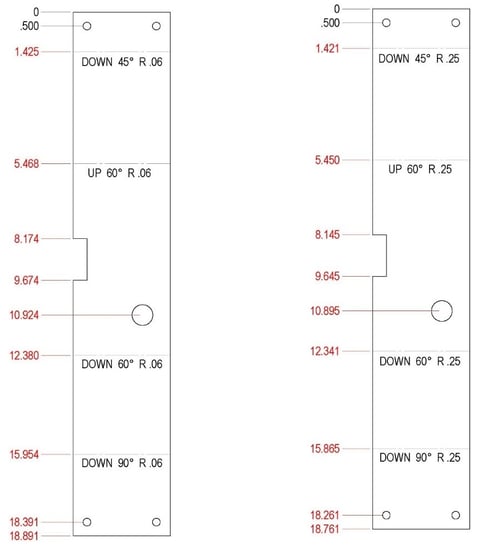

Dimensions given on a flat pattern are affected by several bending factors like k factor and bend radius during the 3d modeling stage.

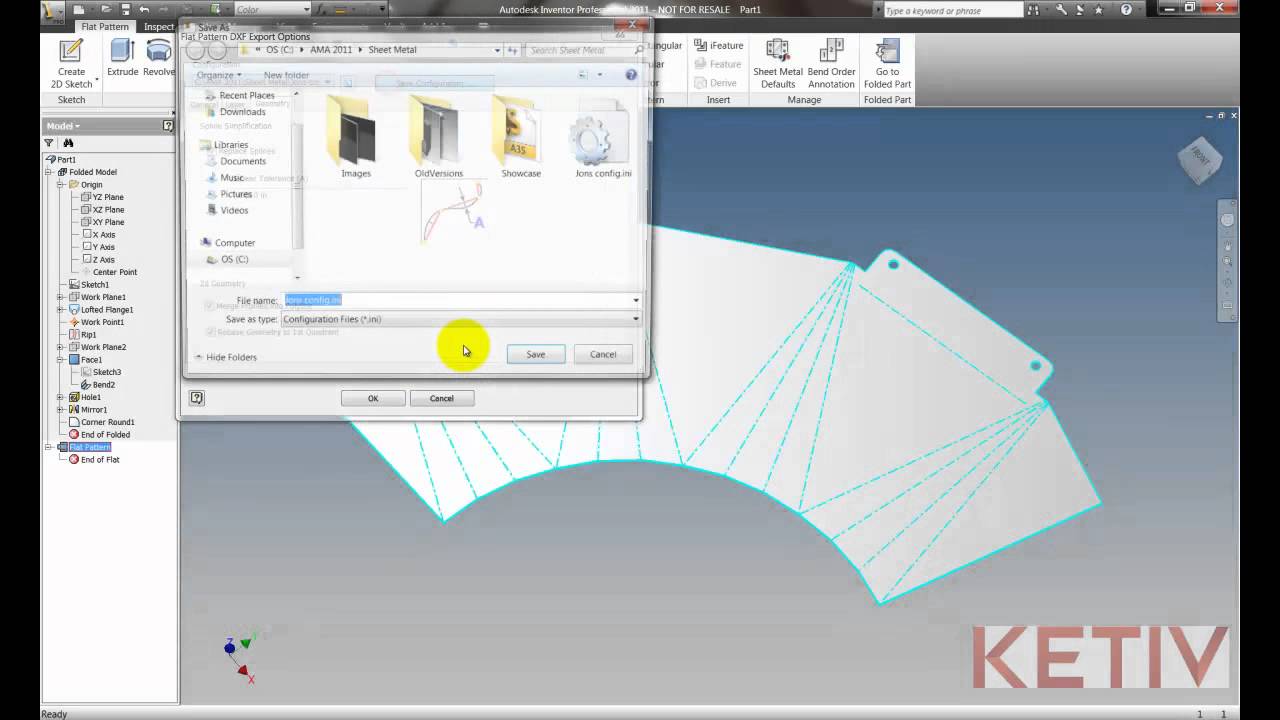

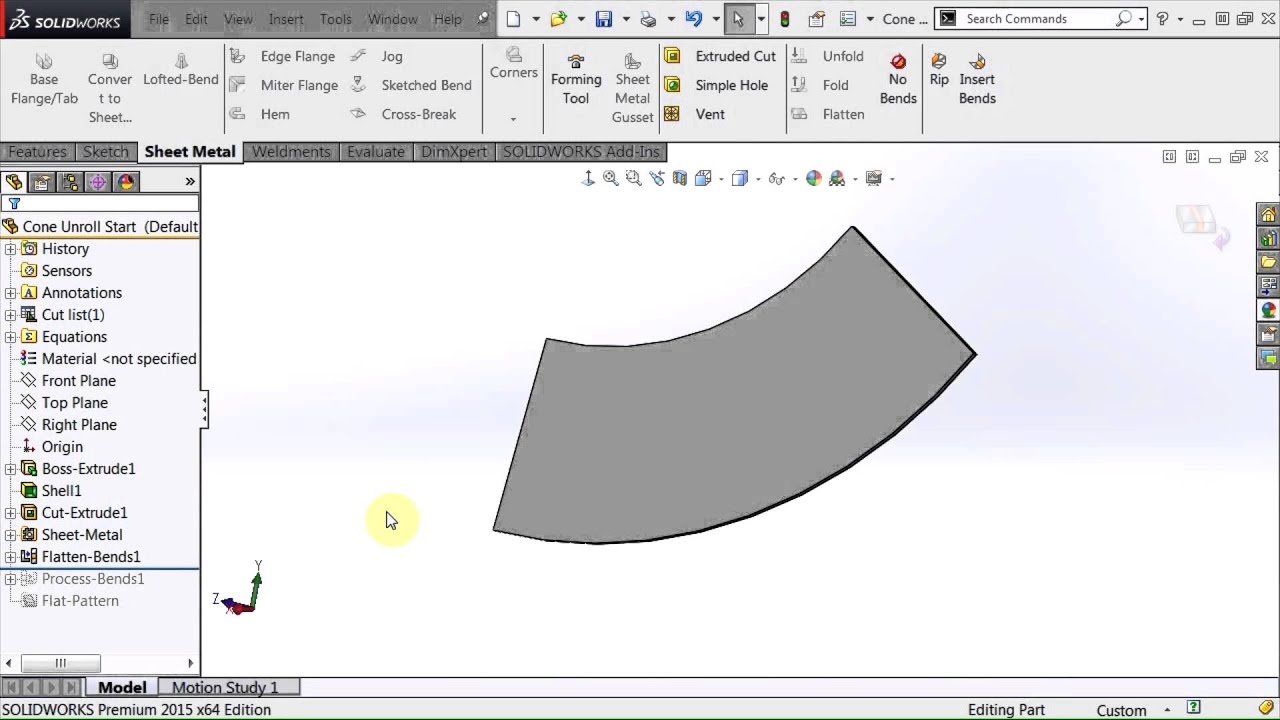

Sheet metal flat pattern drafting. Some of the more common layout tools are scriber flat steel square combination square protractor prick punch dividers trammel points and circumference ruler. And it could well be unstable in case one tries to make changes. Click the flat pattern command. I used a simplified rep state to create the bend back while the flat pattern was excluded.

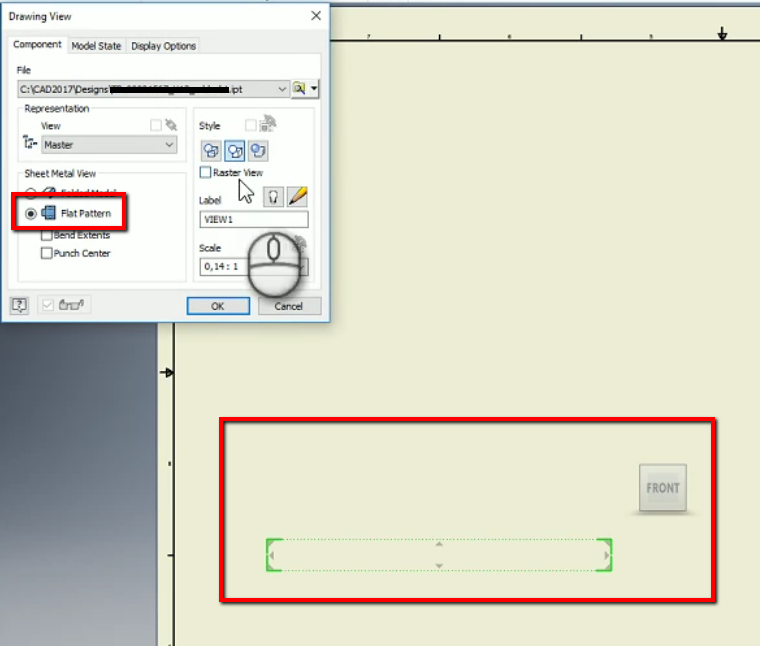

Click place views tab create panel base. In the sheet metal application select the face on the sheet metal model to specify a reference face for flattening. However to match the other dimensions that are included it would require your manufacturer to work with incorrect or unachievable sheet metal. Right click flat pattern and select unsuppress.

However for finished drawings white craft paper is more suitable. Click edit suppress this configuration to suppress all of the selected features. Select process bends and all of the features after it. In the drawing view dialog box select a sheet metal component as file.

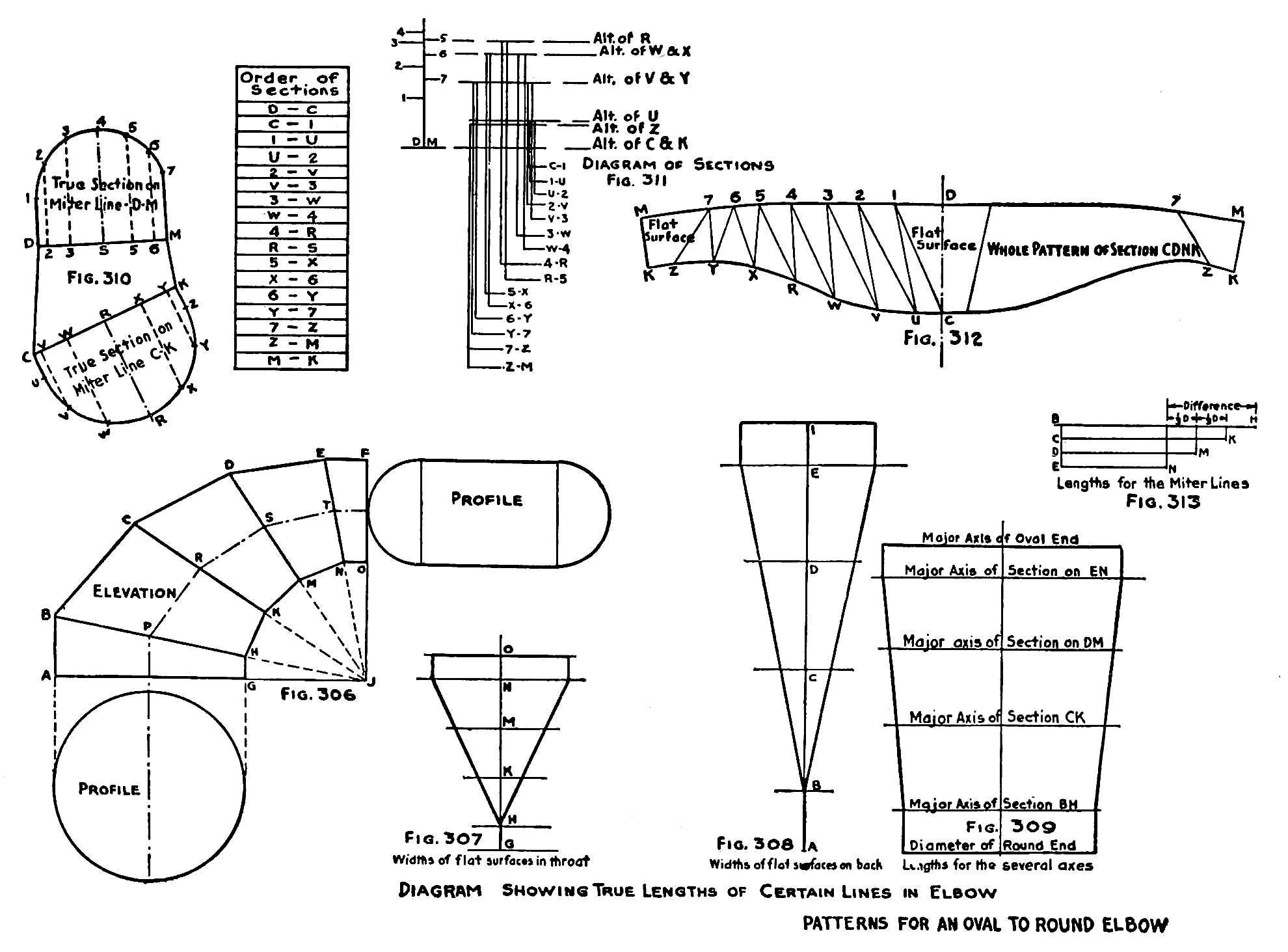

In a sheet metal part create a new configuration. The sheet metal cleat the work of this problem will consist in laying out to full size the views and pattern for a galvanized sheet metal cleat. Layout tools are used for drawing fabrication jobs on metal. Activate the sheet metal application.

The proper relation of views in a drawing. The paper generally used for sheet metal pattern drafting is known as brown detail paper. 1 1 1 scriber lines are drawn on sheet metal with a scribe or scratch awl coupled with a steel scale or a straightedge. To create a flatten view in drafting.

Calculation flat pattern used as a template for cutting the pipe producing with wall thickness s 0. The paper should be of medium thickness very strong and tough because. Set other options in the drawing view dialog and then click in the drawing to place the view. The flat pattern drawing doesn t always list these factors.

In the featuremanager design tree do one of the following. How to dimension a drawing. The select face in the upward face tab highlighted in the flat pattern dialog box. If appropriate select or clear the selection of the recover punch center option.

Flat pattern sheet metal drawing i just confirmed it can be done but it doesn t make sense why. In making the layout for this cleat the following points must be kept in mind. Flat pattern in nx drafting. In the sheet metal view area select flat pattern view.