Sheet Metal Flat Pattern Dimensioning

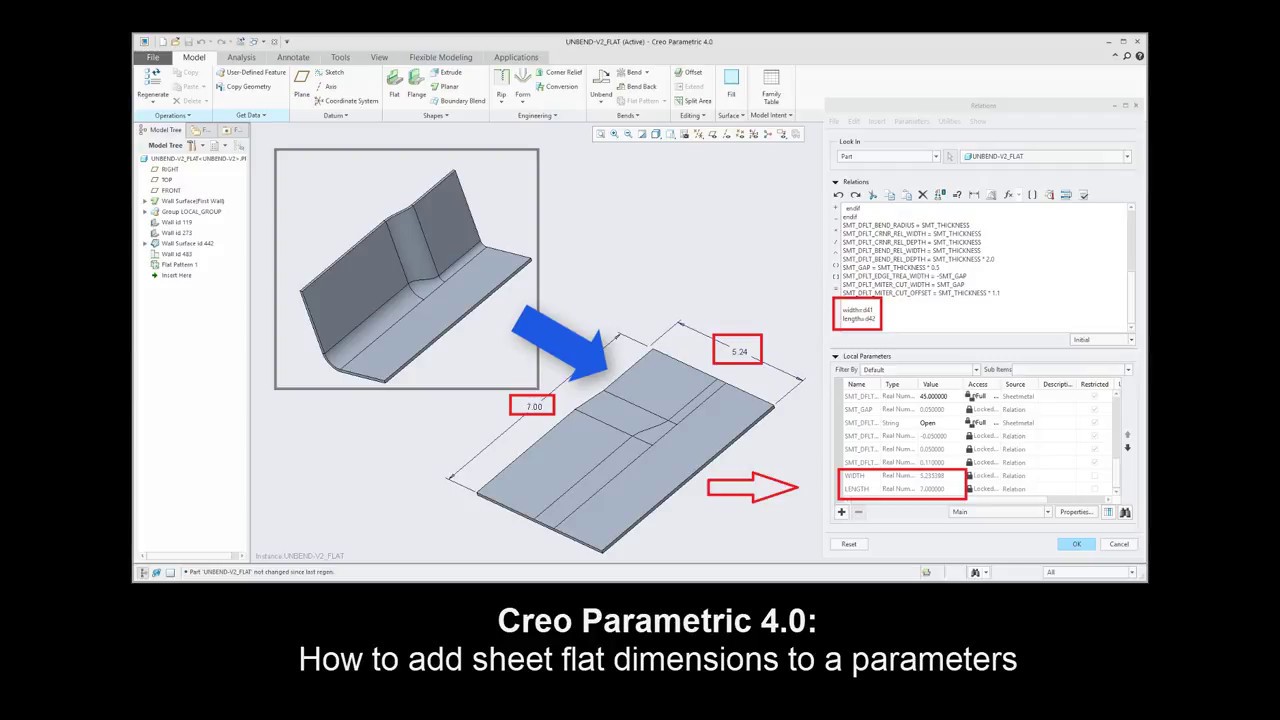

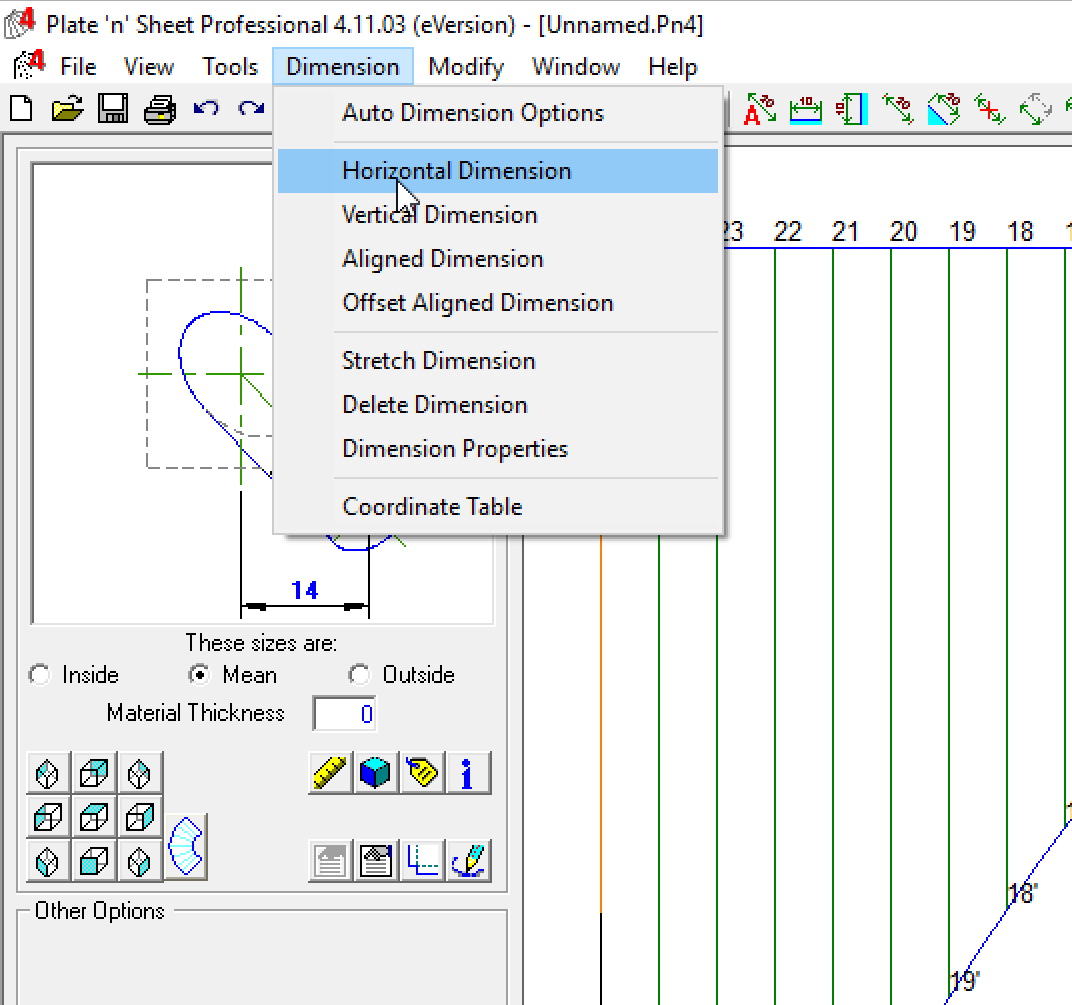

I would like to set precision to 0 1mm and get rid of units mm.

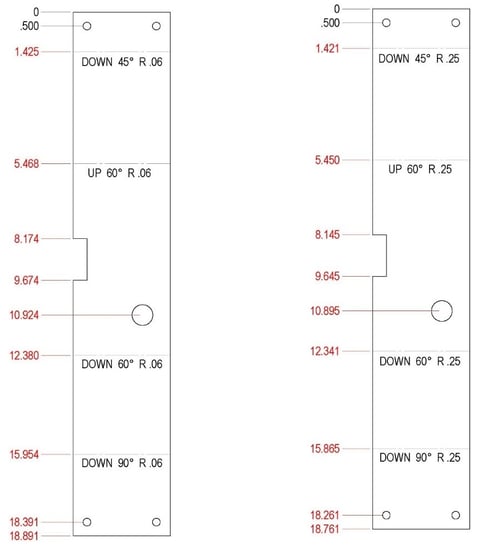

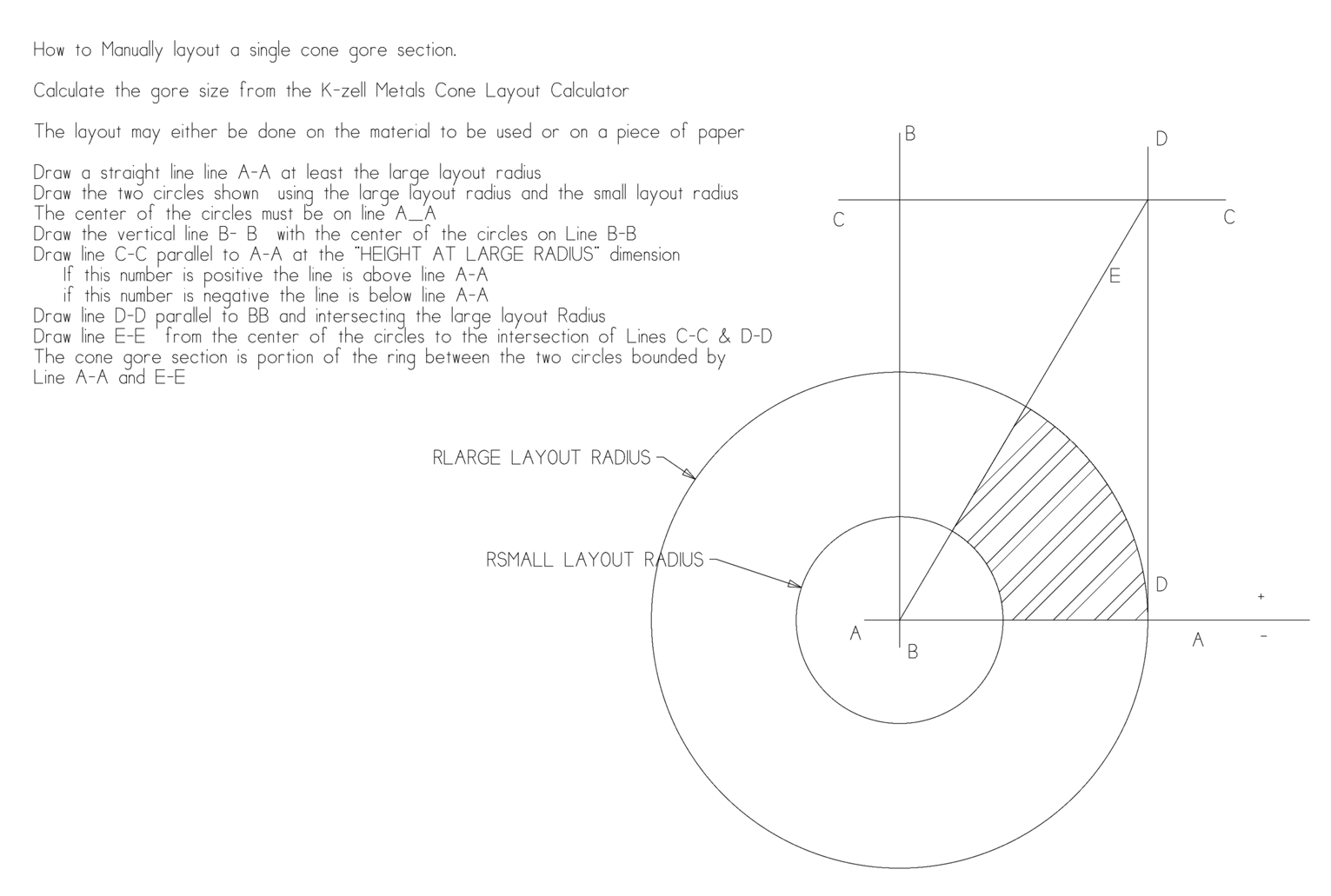

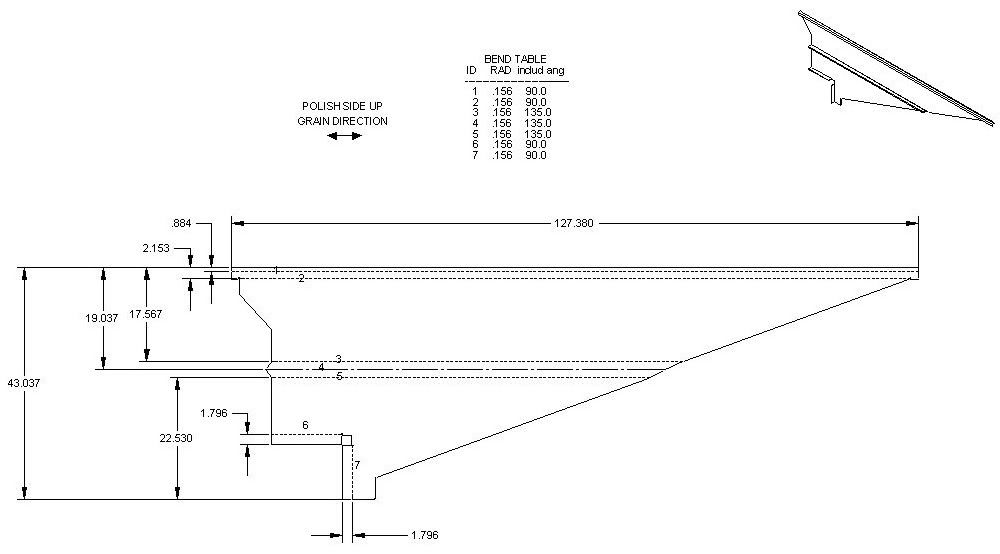

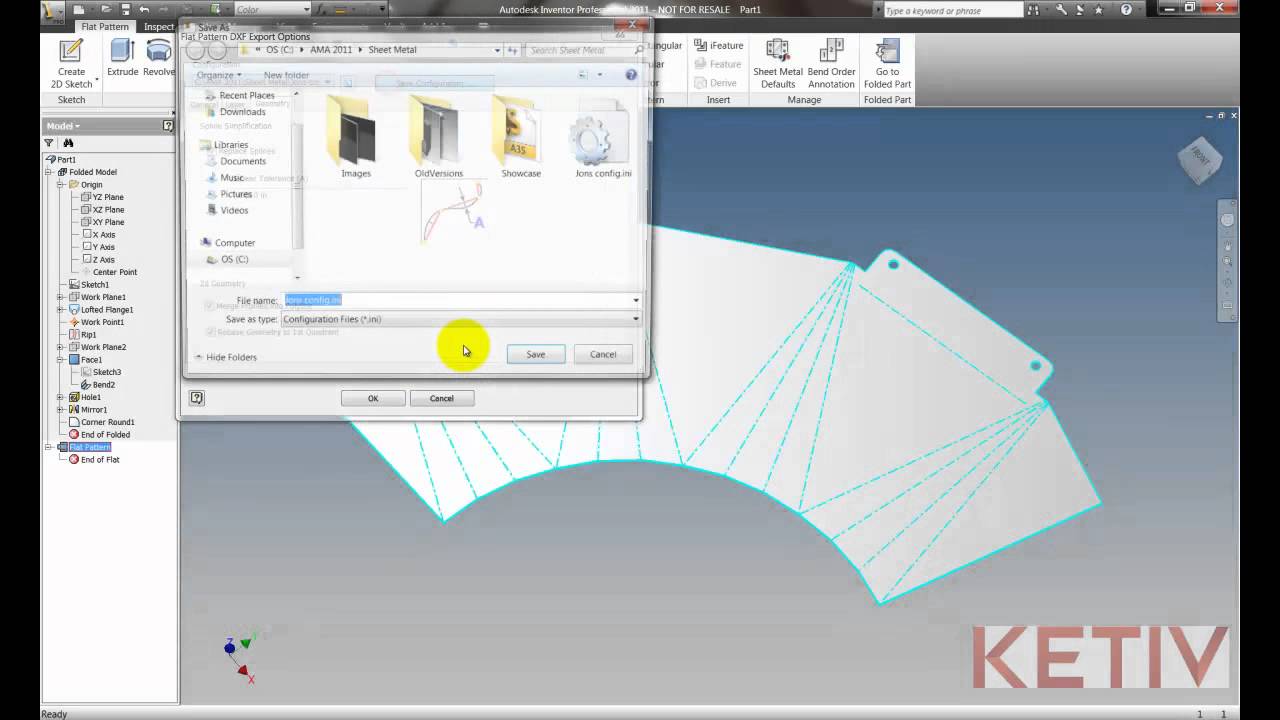

Sheet metal flat pattern dimensioning. With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements. Cells on the right will output the desired values. As one who daily works with sheet metal design and fabrication use outside flange lengths for several reasons. K factor in sheet metal bending is a constant used to calculate sheet metal flat length or flat pattern.

These dimensions may seem helpful but after your manufacturer makes bend deductions based on their capabilities and other bending factors your dimensions will become unusable. You only have to insert interior angle flange lengths k factor inside radius and material thickness. A 1 degree tolerance on all bend angles. Calculation flat pattern used as a template for cutting the pipe producing with wall thickness s 0.

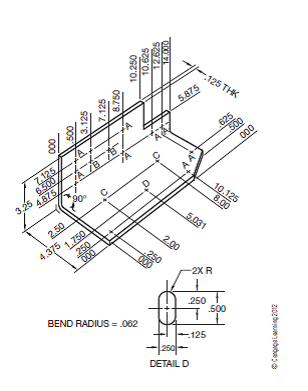

After bending the total length a b is larger than length l. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. You can use this sheet metal flat pattern calculator to calculate this increase in length. Pl thickness x sheet metal width x sheet metal length which looks like this.

Bends in sheet metal are manufactured using sheet metal brakes. For example when sheet metal of length l is bend. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Function goes like this.

I have automated our sheet metal flat pattern dimensions to part iproperties. When you figure flat pattern length you simple add up all the outside flanges and subtract the bend deductions. To know more about sheet metal k factor and flat length calculations. Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

Pl3 0 x 120 79 mm x 250 00 mm.