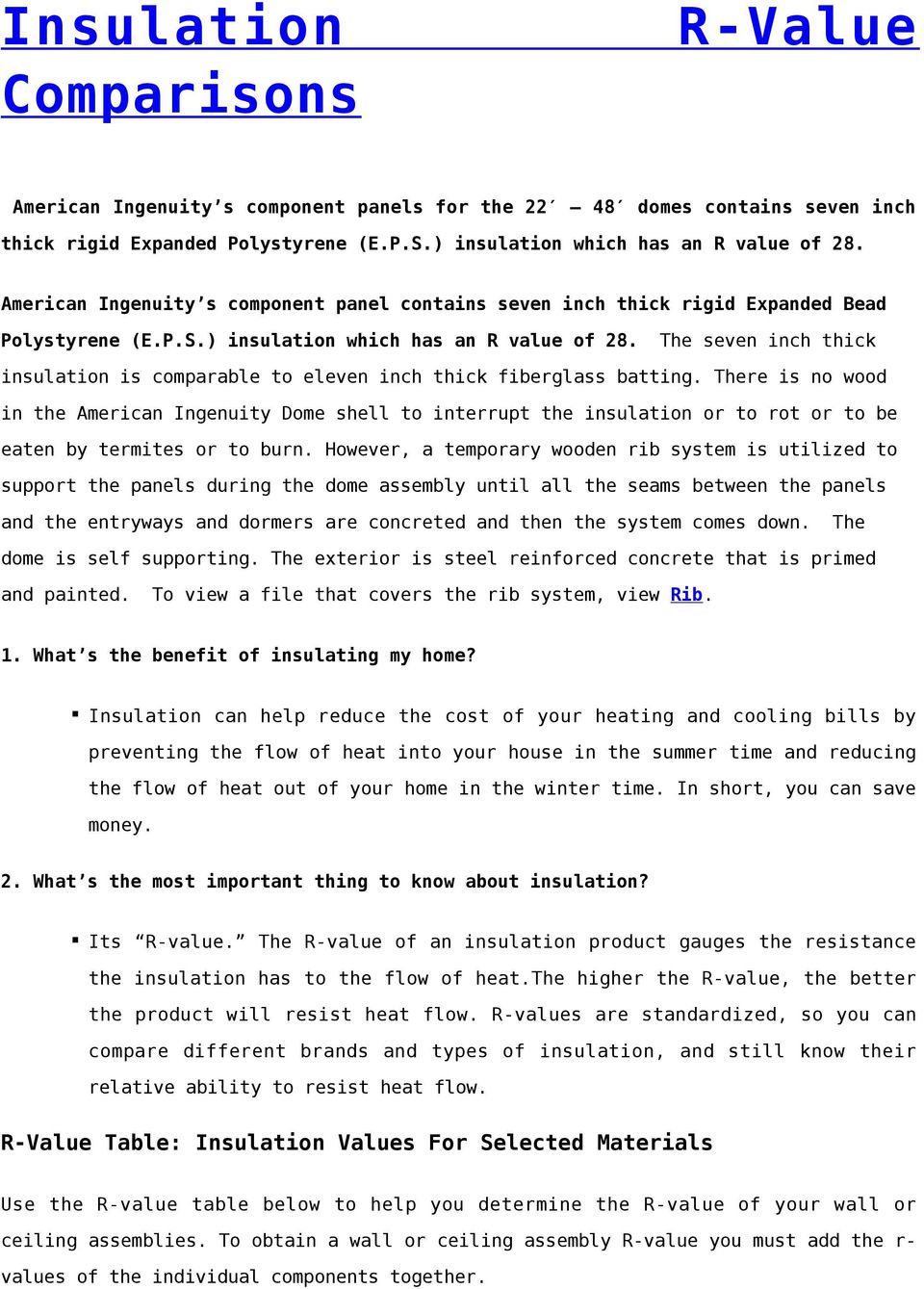

Polystyrene Bead Insulation R Value

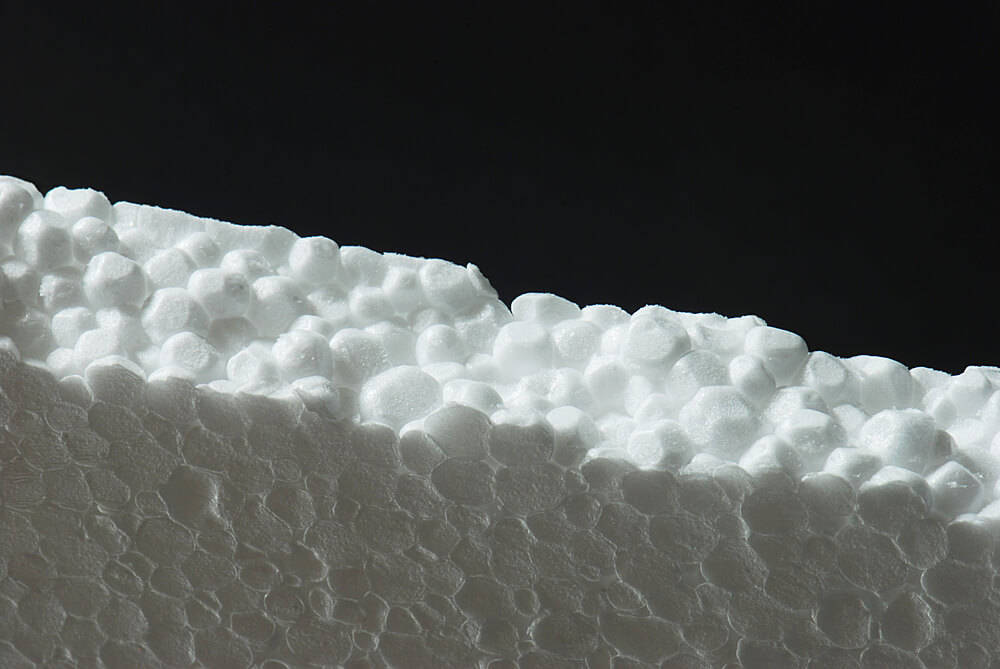

Your images show mechanically crushed eps polystyrene.

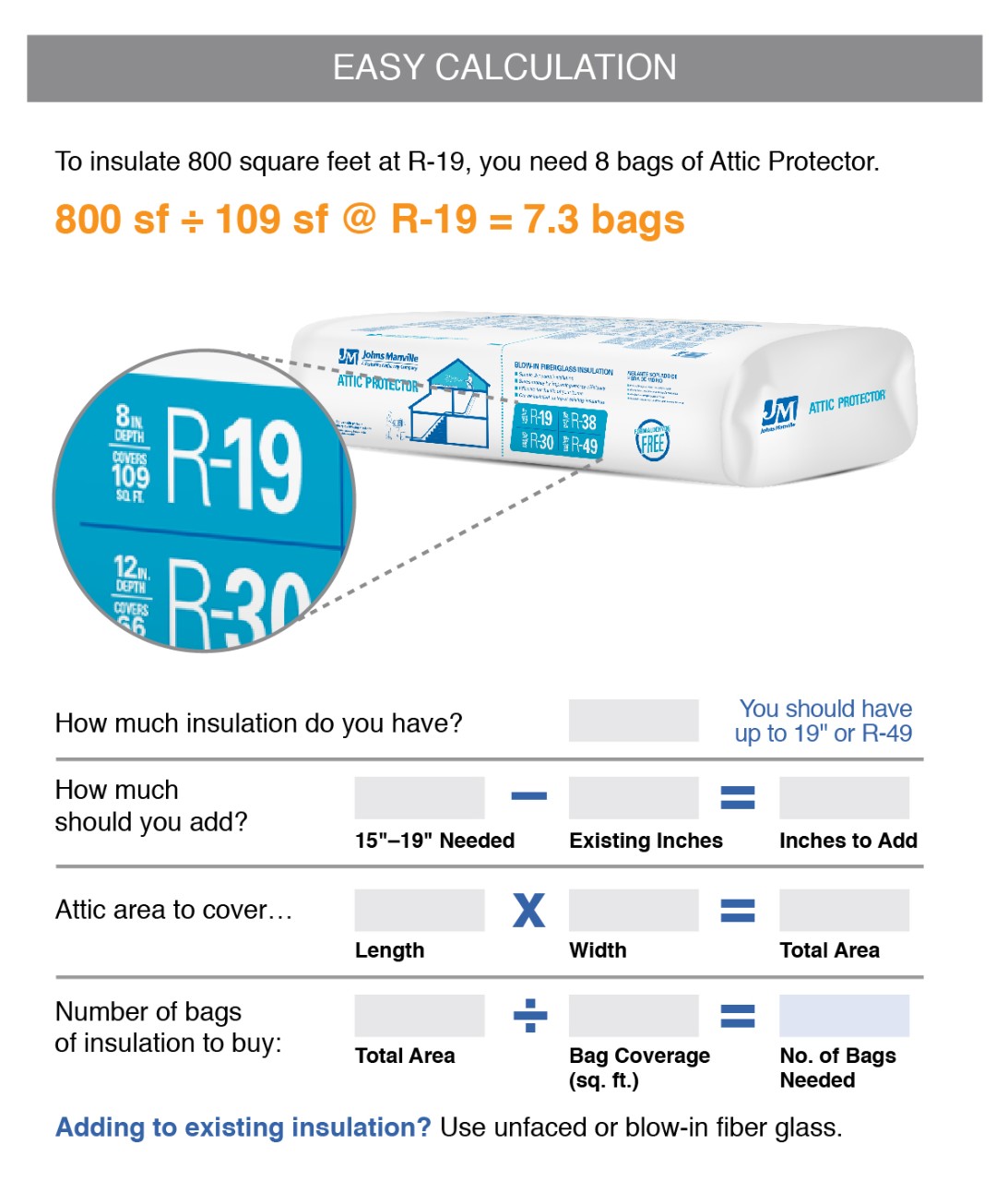

Polystyrene bead insulation r value. If the puffed beads fill the cavity the space can obtain r values close to that of fiberglass insulation. Perlite and vermiculite granular fill offer an r value of up to 2 4 per inch according to the u s. This product typically has an r value of 3 6 to 4 0 per inch of thickness. Material costs are about 0 31 per square foot for each inch of thickness plus installation costs.

It provides r values that range from 3 6 to 4 2 per inch. Expanded polystyrene foam eps is the cheapest and least used foam board product on the market. Department of energy while inspectapedia reports the r value of polystyrene beads at 2 3 per inch. Insulation is a critical component of buildings.

Select 2 to 4 items to compare. Also called styrofoam insulation this is the least expensive material. Polyisocyanurate insulation materials polyisocyanurate or polyiso is a thermosetting type of plastic closed cell foam that contains a low conductivity hydrochlorofluorocarbon free gas in its cells. Garage door insulation spray foam insulation faced insulation soundproofing insulation insulation outdoor roof material high temp material.

Expanded polystyrene made from expanded foam beads that are molded into shape expanded polystyrene or eps is ideal for above grade applications such as exterior walls and offers an r value of 3 6 to 4 2 per inch. Loose fill polystyrene is a hazard. Recent concerns have been raised about the brominated flame retardant hbcd hexabromocyclododecane for the organic chemists among us see flame retardant used in polystyrene to be banned by eu that is found in all polystyrene insulation both extruded. Each type comes with unique advantages.

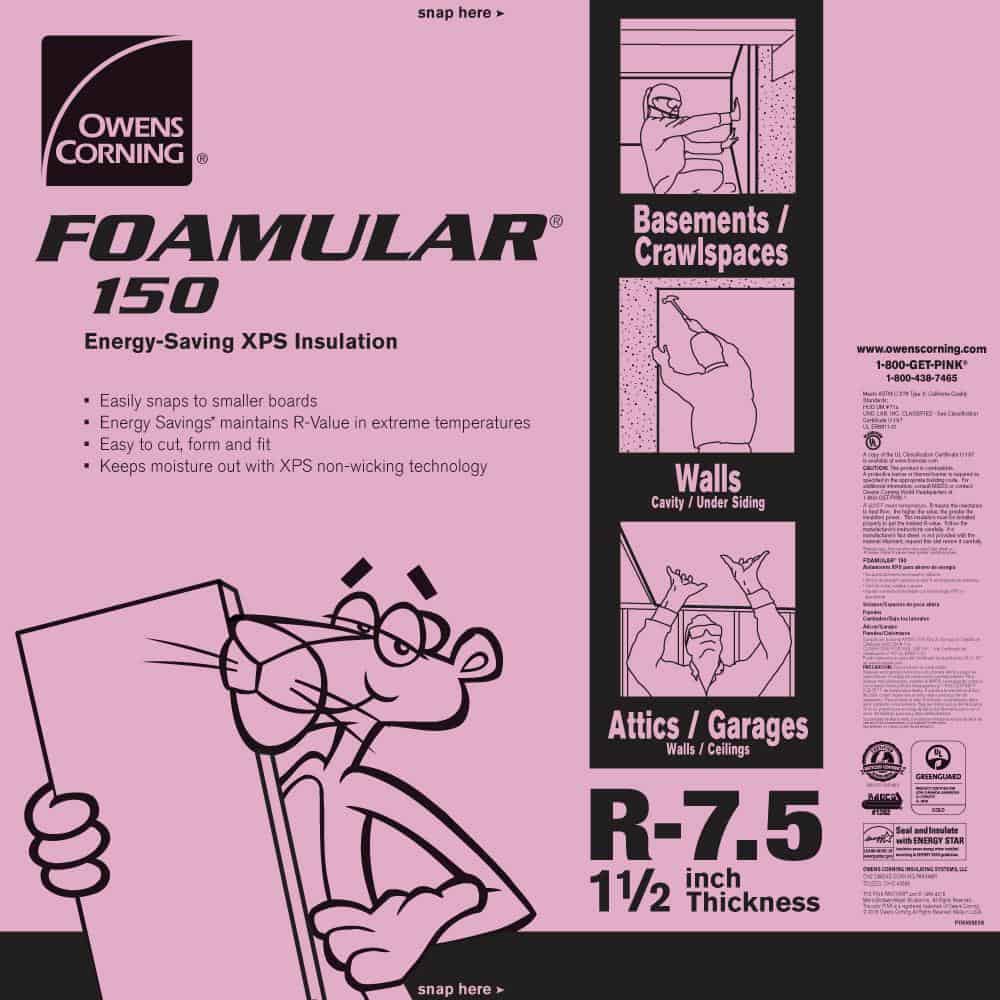

Products with a higher r value have a higher cost but have an increased capacity to resist heat flow and therefore provide greater insulation. Additional r value for a masonry wall constructed using these materials needs to add the insulating value of additional wall components typically included such as 1 solid foam polyisocyanurate r 8 extruded polystyrene r 5 expanded polystyrene r 4 or 1 of perlite r 2 7 and for an exterior air film winter no wind r 0 17 an interior. In this application the puffed beads are poured into the wall cavity between the studs by drilling a hole in the top of the wall.